This review will discuss all three printing techniques, as well as their advantages, disadvantages, and the possibility of future advancements in the field of tissue fabrication.ģD Printing promises to produce complex biomedical devices according to computer design using patient-specific anatomical data. Three promising methods of 3D printing emerged from their research: thermal inkjet printing with bioink, direct-write bioprinting, and organ printing using tissue spheroids. Researchers were interested in not only creating tissue that functioned like natural tissues but in creating techniques for 3D printing that would print tissues quickly, efficiently, and ultimately result in the ability to mass produce fabricated tissues. Fabricated tissue was then measured against this set of standards. To do so, researchers created a set of goals for fabricated tissues based on the characteristics of natural human tissues and organs. As of recent years, the medical field also began to take advantage of the untapped potential of 3D printing for the biofabrication of tissue.

IBOX NANO REVIEW SKIN

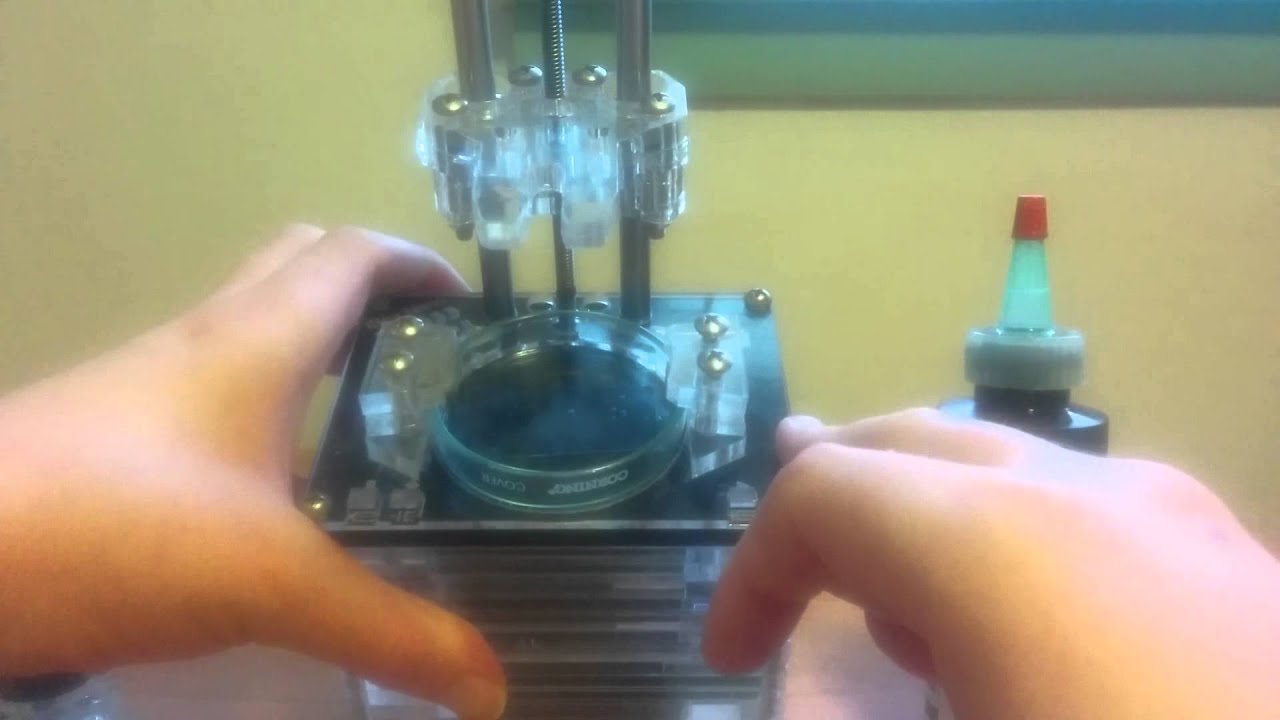

Similarly, research for traditionally engineered skin tissue has been in the works since the 1990s. In this paper, we share the results of our latest research on the 3D printing of crystalline gels on light-induced 3D printers.ģD printing has been around in the art, micro-engineering, and manufacturing worlds for decades. To open up the possibilities for broader application of our crystalline functional gels, we are interested in making them available for 3D printing. Note that the light-induced polymerized 3D printing uses the same principle.

These crystalline gels are synthesized by light-induced radical polymerization that involves light-reactive monomer having the property of curing with light of a sufficient energy to drive the reaction from liquid to solid. We have succeeded in developing them with high toughness, high flexibility, particularly with many functions as shape memory, energy storage, freshness-retaining, water-absorbing, etc. Much of the work in our laboratory revolves around the crystalline gels. Currently the 3D printing machines coming on the market can be broadly classified into three categories from the material state point of view: plastic filament printers, powder (or pellet) printers, film printers and liquid photopolymer printers. 3D printing, also knows as Additive Manufacturing (AM), was first commercialized in 1986, and has been growing at breakneck speed since 2009 when Stratasys’ key patent expired.

0 kommentar(er)

0 kommentar(er)